The class-leading service and breadth of products available from SMC is helping a leading machine builder to maintain and extend its prominent position in a highly competitive global market. HACOS designs, produces and installs high-quality chocolate manufacturing machines that spur the development and growth of every size of chocolatier, from artisans to large industrial producers. The company builds from small to very large machines that cover all chocolate manufacturing processes, necessitating the use of a high-calibre technology partner with a proven track record in industrial control and automation.

By Wim de Vos, Sales Engineer, SMC Belgium

By Wim de Vos, Sales Engineer, SMC Belgium

MARCH 2022

HACOS has its factory in Malle, Belgium, a country renowned worldwide for its excellence in chocolate. However, while there are more than 320 chocolatiers in Belgium, the reach of HACOS extends way beyond its own borders - the company today exports to more than 70 countries. As one of the world’s top 5 chocolate manufacturing machine builders, HACOS produces systems for processes that include moulding, depositing, enrobing, spinning, melting and tempering, and decorating - essentially everything required to transition from raw chocolate block to refined end product.

“That’s why we are widely known as the chocolate machine factory,” states Jan Selderslaghs, Operations Manager at HACOS. “We only produce machines that are befitting of 65 years’ experience and a reputation for Belgian quality. To ensure we live up to our reputation, we leverage the expertise and products of SMC to cover a myriad of motion and control tasks in our machines.”

A fitting start

The partnership began with the supply of SMC KQ2 general purpose fittings for standard pneumatic applications. A discussion about price led to SMC support and the creation of a simple yet highly efficient stock system for fittings that SMC fills twice a week, reducing the need for HACOS to manage its inventory. The success of this system garnered a foundation of trust and HACOS was soon asking SMC for advice regarding technical issues with its incumbent supplier of pneumatic solutions, a large multinational with precious little local support.

SMC takes great pride in the provision of lineside support around the world: 360° customer service is a cornerstone of the company’s business, based largely on direct response, knowledgeable technical advice and close liaison with customers to fully understand the application requirements.

All the motion control and automation products that HACOS needs are available from SMC: pneumatic fittings, FRL units, cylinders, valves and connectors. A good application example is the use of SMC’s KKA fitting, which serves a double-wall container that holds chocolate for heating or cooling prior to moulding. SMC’s KKA-X33 fitting, made from 304 stainless steel, features a special seal to protect against the extremely sticky coolant. In addition, this unique fitting is very easy to clean, which is important as the container often needs cleaning twice a day.

Stainless Steel S-Couples – KKA Series

Stainless Steel S-Couples – KKA Series

Go with the flow

Another product that benefits HACOS is the multipurpose SMC VXZ 2-port solenoid valve. VXZ valves control the cooling water that circulates in the system. This valve has a coil that personnel cannot remove, delivering longer service life for customers. The options used previously by HACOS featured a coil that was possible to disconnect, which was problematic as heat and condensation were entering the valve and causing short circuit situations.

“Around 95% of the machines we manufacture are custom-built” says Selderslaghs. “As a result, we require high flexibility from suppliers such as SMC. Very often we do not know beforehand the exact requirements for the machine’s valves, so we have a permanent need for help with specifications.”

One of the products highlighted by HACOS as providing the required level of flexibility is the new SMC SY, an ultra-versatile 5-port solenoid valve. Many machine builders are overwhelmed when having to decide the best composition of fixed solenoid valve solutions for their application. However, with the new SMC SY there are no more manifold design headaches. This all-purpose valve offers the flexibility to cover all standard applications, improving productivity, optimising air consumption and simplifying machine operation.

5-Port Solenoid Valve – SY Series

5-Port Solenoid Valve – SY Series

In the heat of the moment

Of course, successful chocolate production is all about heating and cooling, which is where SMC’s thermo-chiller technology provides notable advantages. The heating and cooling process must be very precise, typically fluctuating in a range of 0.5°C, from 31 to 31.5°C. Both SMC’s Peltier and rack-type thermo-chillers manage this process perfectly, with the added SMC benefits of compact dimensions and global support on a local level.

In particular, SMC’s HRR rack-type compact chillers enjoy wide deployment in many of the small chocolate manufacturing machines that HACOS produces. Offering temperature stability of ±0.1°C.

Circulating Fluid Temperature Controller, Rack Mount Type – HRR Series

Circulating Fluid Temperature Controller, Rack Mount Type – HRR Series

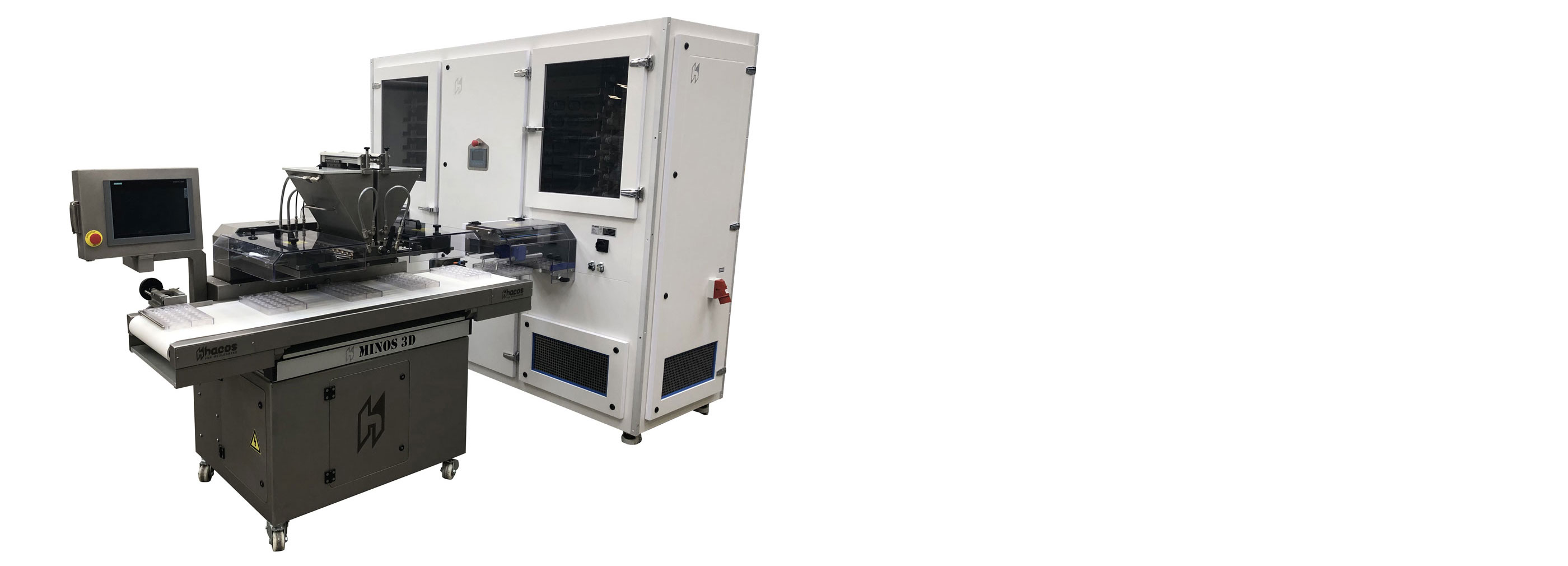

HACOS MINOS Automatic One Shot Molding Line One shot dosing machine with cooling tunnel and automatic demoulding system. Suitable for: Dosing One Shot - Form pralines – Tablets

HACOS MINOS Automatic One Shot Molding Line One shot dosing machine with cooling tunnel and automatic demoulding system. Suitable for: Dosing One Shot - Form pralines – Tablets

“SMC offers quality products and the brand is well-established and a symbol of quality around the globe, so our end users are happy to have SMC components in their machines,” says Selderslaghs.

One of the technical challenges is that these components need to be very compact in almost every case. However, SMC is renowned for providing solutions featuring small dimensional envelopes, helping machine builders to reduce the size of their systems and minimise energy consumption. For instance, SMC recently supported HACOS in the development of a robot with very small valves and cylinders, as it was necessary to account for every single gram of mass.

“Beyond high-quality products, it’s really all about the service that SMC provides, both local and global,” concludes Selderslaghs. “SMC are on site twice every week, not just to replenish stock, but to support us with any technical challenges or answer any questions that may arise. We also benefit from SMC’s global presence, which ensures good service and support in any part of the world where our machines are in use.”