By Thomas Greif | Senior technical support engineer mechatronics & network, SMC Italia

By Thomas Greif | Senior technical support engineer mechatronics & network, SMC Italia

MARCH 2024

Imagine you’ve just identified an electric actuator as your preferred way to facilitate a particular machine movement. Great, right? Well, yes, but then you might be confronted with too many queries, too many options to select that optimal electric solution. In this article - and based on our conversations and the support we provide to our customers - I want to delve into those initial questions that could help shed some light on the matter.

SMC´s Easy to operate electric actuator, EQ Series – Just easy

SMC´s Easy to operate electric actuator, EQ Series – Just easy

Belt or ball-screw drive?

A primary consideration is selecting between an electric actuator with a belt or ball-screw drive. The choice mostly hinges on the specific application and system requirements. Unless the machine requires an exceptionally long stroke, most precision motion control applications benefit from an actuator with a ball-screw drive. These actuators achieve a repeatability of ±0.01mm, while belt-driven types perhaps only ±0.08mm.

Another reason is safety. Electric actuators with a ball-screw drive benefit from the mechanical connection of a ball nut screw. From an engineering perspective this design presents a far more robust and hence safer concept, especially in vertical applications. Belt-driven actuators need a supplementary safety component that avoids movement of the vertical load, particularly in the event of belt damage.

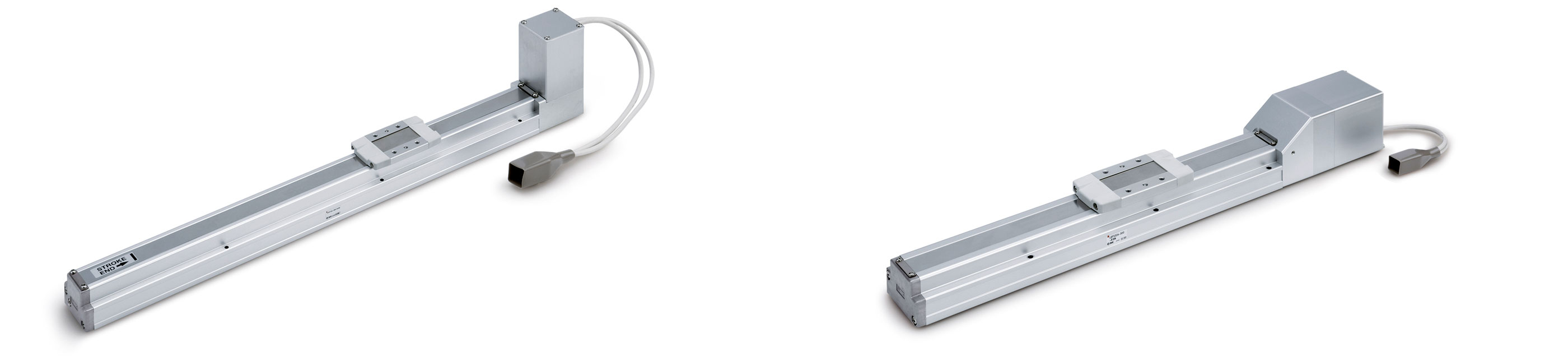

SMC´s Electric actuator, Slider type, Belt drive – LEFB Series

SMC´s Electric actuator, Slider type, Belt drive – LEFB Series

SMC´s Electric actuator, Slider type, Ball screw – LEFS Series

I know what you’re thinking: aren’t ball-screw drives slower? Technically, yes, the maximum speed is indeed slower than belt-driven counterparts. However, in a movement composed of at least three phases (acceleration, constant speed movement and deceleration), it’s not always possible for a belt-driven actuator to reach its maximum speed. It may come as a surprise to some that the overall positioning time of an electric actuator with a ball-screw drive is often equal to or sometimes less than that of a belt-driven alternative, especially in shorter stroke applications up to 800 mm.

A further challenge is high-load applications, where belt wear will demand periodic checking and tensioning. During this operation, your belt will likely extend, and in applications with precise positioning you’ll have to recheck and possibly adjust all your saved positions. In contrast, an electric actuator that deploys a ball-screw drive is maintenance-free.

Stroke versus speed

Another issue familiar to any knowledgeable supplier of electric actuators is that increasing the stroke of an electric ball-screw actuator reduces its maximum speed, an effect caused by construction limitations.

Here, two main factors are significant: rotational speed and the unsupported length of the screw. If we increase the stroke beyond a certain value, we must lower the rotation speed of the screw so as not to go into resonance, thus reducing the linear speed of the actuator.

SMC´s Electric actuator, Large slider type, Belt drive – LET-X11 Series

SMC´s Electric actuator, Large slider type, Belt drive – LET-X11 Series

In order to meet performance requirements, it’s necessary to use different screw pitches for ball-screw actuators. And when increasing the pitch is no longer sufficient, you’ll need an actuator model with intermediate supports that reduce the distance between the nut and bearing to avoid resonance.

Stepper or servo motor?

Yet another common dilemma relates to the motor. Which is best: stepper motor or AC servo motor? Again, supplier know-how and expertise suggests that motor choice is not always straightforward, as particular specifications, personal preference and cost all come into the equation.

Torque is a frequent differentiator when it comes to motor sizing. Not just the nominal torque, but also the torque relating to the motor’s rotational speed. While AC servo motors are able to deliver the nominal torque for the entire nominal speed range, say 3000 rpm, stepper motors deliver the maximum torque at a very reduced speed. Increasing the speed means torque decreases significantly.

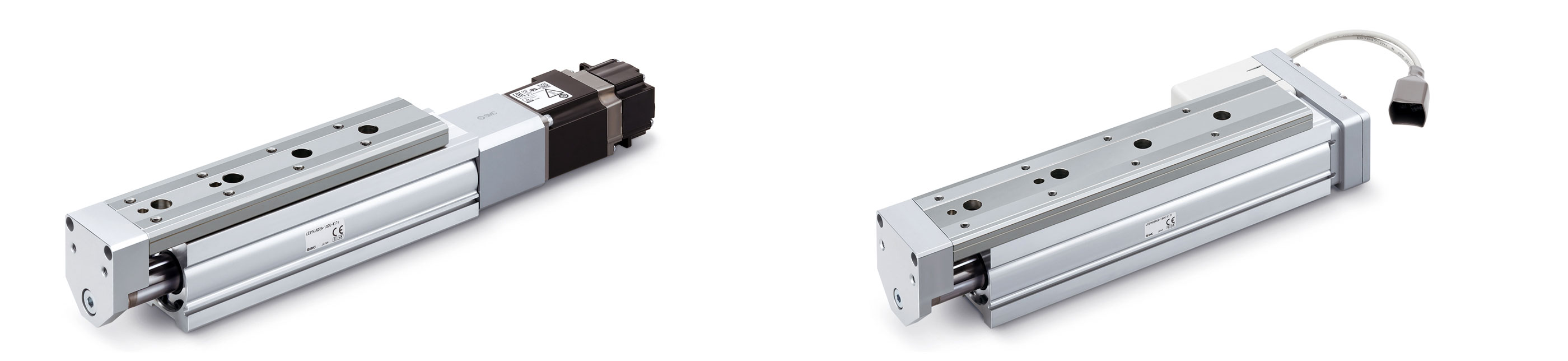

SMC´s Electric actuator, AC servo motor – LESYH Series

SMC´s Electric actuator, AC servo motor – LESYH Series

SMC´s Electric actuator, Step motor – LESYH Series

In short, an electric actuator with a stepper motor is able to perform work at low speeds competently. However, an AC servo motor becomes preferable if greater dynamism is necessary.

Replacement

Experience and knowledge are equally important in aftersales applications. We encounter many customers looking to replace a discontinued drive, for example. The answer to this conundrum is to use a supplier with an ethos of developing new-generation products that are 100% compatible with the legacy model. Most find that while the new drive is dimensionally the same, it will offer a number of new advantages, perhaps relating to control or safety.

SMC´s Step motor controller with STO sub-function – JXC#F Series

SMC´s Step motor controller with STO sub-function – JXC#F Series

If you require support with product selection, application assessments, design or improvement activities, we can help overcome all of your motion control challenges, including those involving electric actuators. Whether it’s a pre-sales or after-sales request, you’ll find that seeking expert advice will always prove invaluable.