The challenge with maintenance is that it’s an indirect cost with a direct impact on bottom-line profitability. Most manufacturing plants resign themselves to think it a necessary function, deploying all kinds of strategies to try and minimise the associated costs, typically preventive or predictive maintenance. While these approaches save costs in a variety of ways, there is another strategy that pays even higher dividends: no need for any maintenance. Simply by choosing quality products proven to offer long-term reliability in the given environment and working conditions, you can reduce your maintenance requirements and costs considerably.

By Mario Sánchez, Product Specialist Sales Team Manager, SMC Spain

By Mario Sánchez, Product Specialist Sales Team Manager, SMC Spain

APRIL 2023

By looking to extend the lifetime of your automation components and, in turn, your machines and systems, you not only reduce MRO (Maintenance, Repair and Overhaul) costs, but also promote higher productivity OEE (Overall Equipment Effectiveness) and machine availability. Unproductive machines due to poorly specified products have a highly negative effect on profitability, while energy efficiency also suffers because damaged or compromised components, such as filters and actuators, increase energy consumption.

To avoid these outcomes and help reduce your maintenance costs there is a clear, three-step pathway: choose high-quality products; choose according to the application and working environment; and choose condition-optimised components.

Choose high-quality products

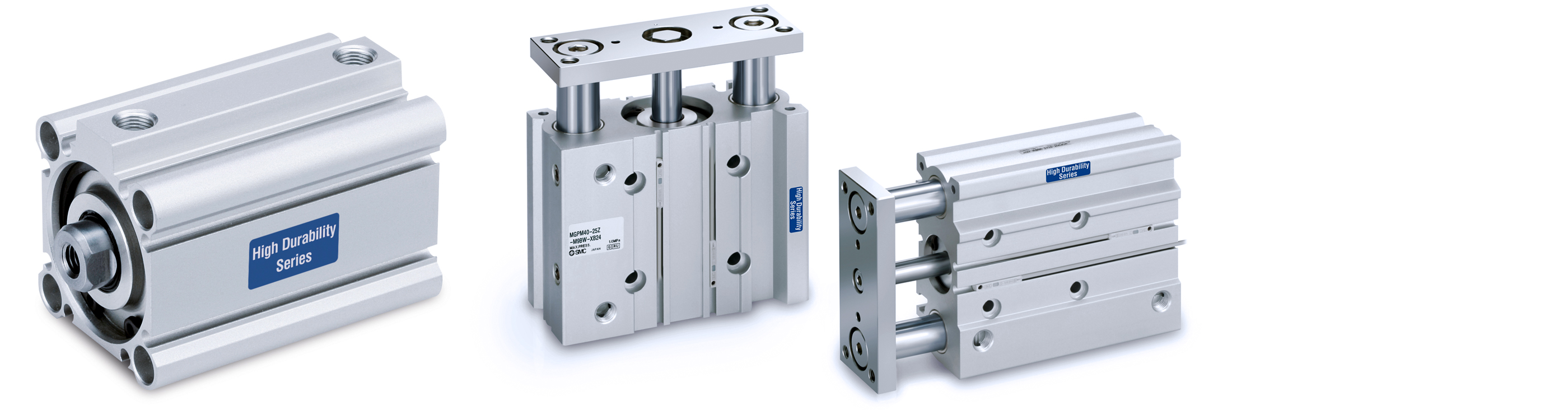

One of the principal routes to reducing your maintenance burden is through astute component selection. Choosing high-quality and high-durability automation components sounds like an obvious suggestion, but the sums add up. Despite the slightly higher initial investment, the aforementioned gains far exceed the additional purchase price, leading to significantly lower TCO (total cost of ownership).

SMC´s Long Life Cylinders

SMC´s Long Life Cylinders

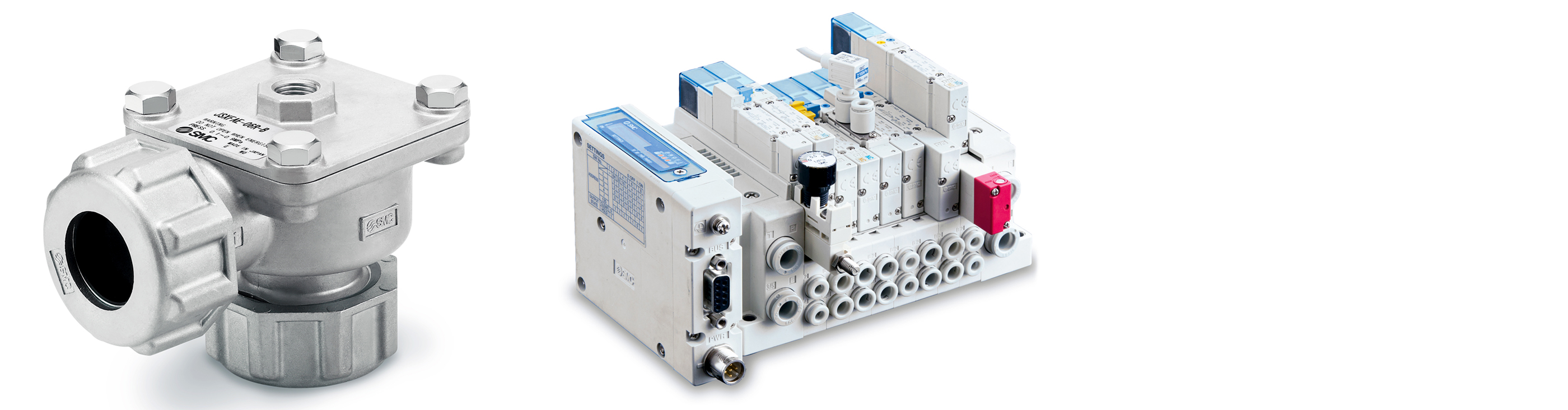

If you are unsure which components to select, speak to our experts. We regularly provide customers with technical support, identifying the optimal automation components to help maximise lifetime, including standard parts such as tubing, fittings, valves and clamping/mounting systems. Whether it is a spring-free pulse valve offering 10 million cycles (10 times longer than a standard component), a metal sealing valve offering 200 million cycles (four times longer) or a high-durability actuator (four times longer), the opportunities to reduce costs are clear.

SMC´s Pulse Valve – JSXF# Series; 5-port Solenoid Valve – SY Series

SMC´s Pulse Valve – JSXF# Series; 5-port Solenoid Valve – SY Series

Choose according to the application and working environment

Aside from quality, it is also necessary to select components based on the operating environment. Factors such as temperature, humidity and airborne dust all have the potential to compromise the lifetime of your components, so shrewd selection again yields results.

Actuators, for example, are available with a range of options that provide protection against the environment. Here, the use of a lubrication retainer prevents micro-dust from contaminating the grease film that forms on the cylinder rod surface. Further actuator solutions, such as a reinforced scraper prove better in environments exposed to dirt or sand, while a metal scraper serves to get rid of frost, ice, weld spatter or cutting chips adhered to the rod, thus protecting the seals. A protective cover/bellows is beneficial in particularly arduous environments.

Another key factor in the selection process is the potential for components to resist wear and fatigue. For instance, adopting a wireless control system, rather than using conventional cables, reduces any opportunities for wiring to become loose, trapped, abraded or compromised in any way. Similarly, your tubing and fitting selection might need to take into account issues such as UV, abrasion or cleaning chemicals if you want to ensure it lasts for the lifetime of the machine.

Choose condition-optimised components

Also worthy of scrutiny is the working condition of your system. Pressure, for example, can place significant strain on components such as seals. Lowering your system pressure from 6 or 7 bar, to 5 or even 4 bar, considerably reduces maintenance and the risk of failures, while also contributing greatly to energy efficiency. However, while the vast majority of applications still function normally at reduced pressure, you should always seek professional advice before taking this action.

Another consideration is the use of stand-by valves. Lowering the pressure when machines are at rest extends the fatigue life of seals and, in turn, prolongs the useful life of your components. A further option is the deployment of soft-start valves, which protect pneumatic components and reduce pressure surges at start-up and pressurisation.

SMC´s Filter Regulator Unit with Residual Pressure Relief 3-port Solenoid Valve with Soft-start Function

SMC´s Filter Regulator Unit with Residual Pressure Relief 3-port Solenoid Valve with Soft-start Function

Compressed air quality also requires your attention as it is necessary to control the humidity, temperature and particle content of compressed air to help extend the service life of system components. Water condensate is a particular hazard as it damages seals and lubricant.

Significant ROI

Today, improvements in automation solutions found in ‘brownfield’ machines make them highly suitable for specification in new (‘greenfield’) machines. The return on investment provided by these high-durability components speaks for itself: you save on the cost of replacements, maintenance time and machine downtime, and make gains in OEE and energy efficiency. In addition, safety increases as it reduces the risk of unexpected failures, while sustainability also gets a boost: long-life components mean less industrial waste and fewer replacements.

Whether you are an OEM working under warranty or a service contract, or an end user with your own maintenance team, component selection is vital if you want to drive down maintenance costs. However, if you are unsure about selecting the right parts, speak to our expert team here at SMC. We can provide assessment based on our expertise in system analysis to make the best recommendations for your application.