Given that we acknowledge the environmental impact of the production process, we aim to be more efficient while lessening it at the same time

Back in 1998, SMC Corporation began to make an organisational effort in implementing environmentally friendly and energy-saving measures in our factories.

Addressing scope 1 & 2

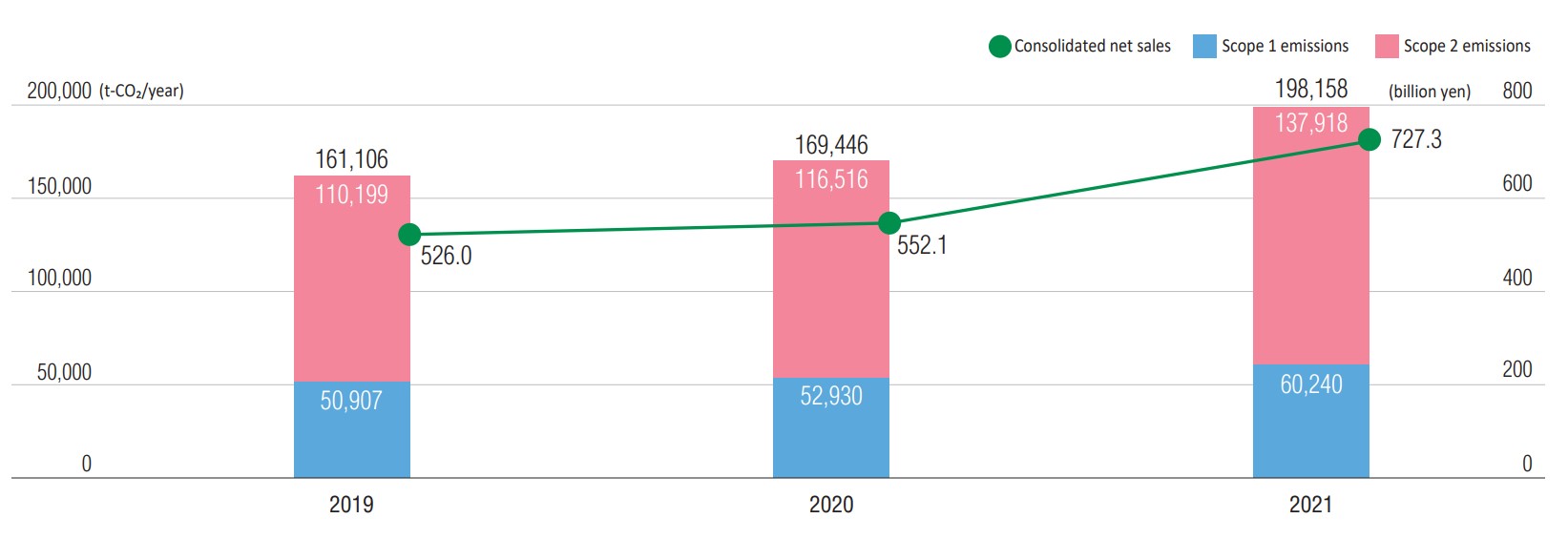

SMC is promoting various initiatives to reduce greenhouse gas (GHG) emissions produced by our own production activities.

We recently completed the compilation of data covering the entire Group*2 on Scope 1 and Scope 2*1 emissions

based on the “GHG Protocol” international standard.

As we expect the scale of our sales and production to increase, we have built many specific policies and formulated medium- to long-term targets*3 to reduce our overall levels of GHG emissions.

*1 Scope 1: CO2 emissions produced by the Company's own fuel consumption.

Scope 2: CO2 emissions produced through the consumption of energy supplied by other companies.

*2 The 34 locations, which include sales locations, mass production locations, and major distribution centres, make up more than 95% of consolidated

external net sales.

*3 Reduction targets to meet the demands of SBTʼs 1.5°C scenario with FY2021 as the base year.

SMC Groupʼs GHG emissions (Scope 1 and Scope 2)

TCFD commitment

In June 2022, SMC expressed our commitment to the TCFD. Climate change presents financial risk to the global economy.

Financial markets need clear, comprehensive, high-quality information on the impacts of climate change. This includes the risks and opportunities presented by rising temperatures, climate-related policy, and emerging technologies in our changing world.

The Financial Stability Board created the Task Force on Climate-related Financial Disclosures (TCFD) to improve and increase reporting of climate-related financial information.(https://www.fsb-tcfd.org/)

Handling chemical substances with care

We strive to eliminate the use of CFCs (chlorofluorocarbon) by switching to alternatives with lower GWP (Global Warming Potential) values.

We are also working in reducing the overall use of chemical substances through the prevention of evaporation, prevention of removal, and reuse.

1% yearly reduction in energy consumption is our target

As a part of the SMC Corporation’s adherence to the Japanese Act on Rationalising Energy Usage, we commit to a yearly reduction of 1% in our energy consumption. This affects our 6 Japanese production centres, as well as the Japanese Technical Centre.