The SMC products used in Colorservice's automatic plants are key components in ensuring reliability in continuous plant automation and perfect dosing of the raw materials used in the manufacture of tyres from all the world's leading manufacturers. In order to guarantee the highest level of tyre safety and performance, the numerous raw materials that make up tyres must be dosed to perfection. Modern tyres can require dozens of raw materials and additives for their manufacture, which must be carefully mixed and dosed according to the specific recipe required.

The compounds used to make rubber products contain a number of materials in the form of powder, chips and liquids, the correct mix of which determines the characteristics of the finished product.

Using Colorservice's equipment, the raw materials and additives defined in the recipes are automatically bagged and delivered to the customer's mixer without human intervention. As Antonello Turle, Vice President and Head of Experimentation Projects at Colorservice, and Project Manager Massimo Pettenuzzo explain, "our automatic machines make the bag containing the compound that will be used to make the tyres through the vulcanisation process, fill it with the perfectly dosed recipe ingredients and seal it, guaranteeing maximum product uniformity."

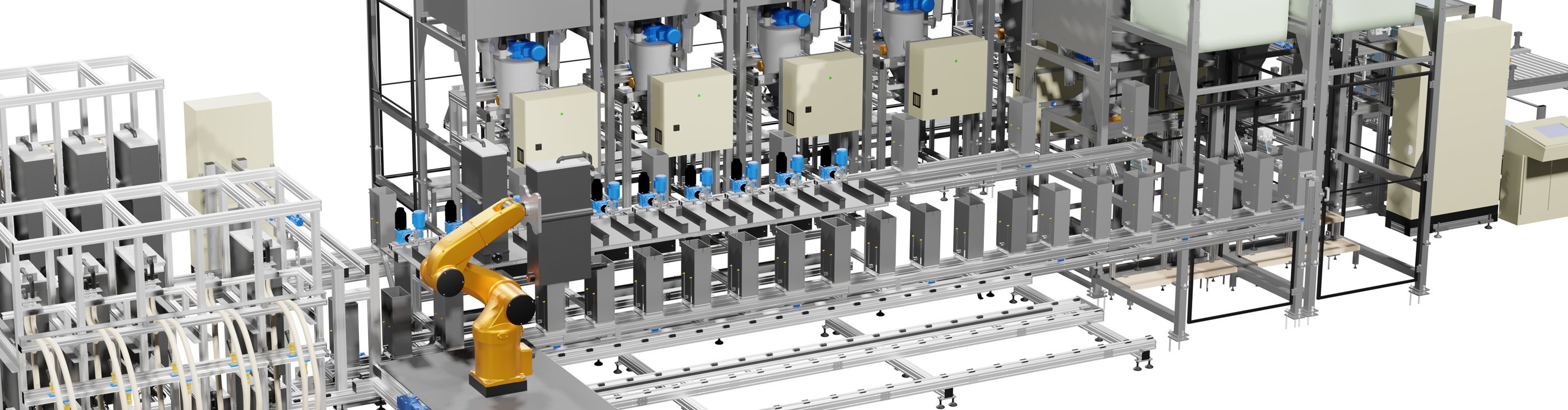

Automatic dosing system for weighing components for tyre production.

Automatic dosing system for weighing components for tyre production.

Accuracy and traceability

Presently, the automotive industry demands a level of absolute quality and detailed traceability, right down to the sources of the raw materials, for all the elements of vehicles that determine their safety, of which tyres are obviously a part.

Mr. Turle presses on: "Our customers need to obtain a final mixture that is always the same and is reproducible, without exception; a requirement that is in fact impossible to meet with the traditional manual methods of weighing and preparing mixtures used in the past. Our patented multi-component dosing system, on the other hand, guarantees absolute uniformity of the finished product and its full traceability."

Each automatic dosing line created by Colorservice is customised to the specific needs of the customer and the production site where it will operate, but they all share the same basic architecture, which uses a wide range of SMC components for the entire pneumatic automation system.

Mr. Turle comments: "In the pneumatic field, we know that whatever component we need, we are sure to find it in the SMC catalogue. But it is not only the ample range on offer in their catalogue that has consolidated our partnership. SMC´s constant willingness to assist us during the research and development phase of new solutions, particularly those that are technologically more advanced, has been equally fundamental. For example, in one of our most recent projects, with the help of SMC's local structure, we successfully tested the use of the IP Series positioners, PF Series flow meters, and VP Series safety valves, which allowed us to further improve dosing accuracy, perform a safe shutdown when necessary, and significantly reduce compressed air consumption when restarting the plant. In particular, the use of these elements has allowed us to guarantee maximum plant safety without sacrificing productivity."

Endurance and environmental sustainability

Another key feature of Colorservice's automatic multi-component dosing plants is their ability to work reliably even in the harshest environments, such as those typically found in tyre mix preparation, where the presence of dust is unavoidable.

A dusty environment is not only unhealthy for human operators, but also puts the reliability of machines at risk if they are not designed with these requirements in mind. Furthermore, given the extreme competitiveness of the tyre industry, production plants typically work 24/7, with very little time dedicated to scheduled maintenance. As Mr. Turle explains, "one of our strengths that has helped make us the world leader in this sector is the extreme reliability of our automatic machines. For this reason, we in turn need extremely reliable components, and from this point of view, experience with SMC has been exceptional: reliable products, even when working in dusty and difficult environments."

For the benefit of environmental sustainability, Colorservice's automatic dosing systems have a whole series of vacuum cleaners to recover dust during their handling, both to comply with increasingly stringent health regulations and to improve workers´ environmental well-being.

Mr. Pettenuzzo concludes: "sustainability is another important value that we share with SMC. Building pneumatic systems that consume less air, recovering dust, protecting people and machines from the risk of chemical contamination by using appropriate components. There are many technical aspects that must be taken care of, and in all this SMC has been of great help during the experimentation of all the innovative solutions we have devised. The excellent spirit of cooperation between a large multinational like SMC and a relatively small company like Colorservice is a source of pride for us, and a very positive factor that allows us to be even more credible and competitive in markets all over the world."