SMC, the world leader in pneumatic automation, and DMC Automation of Turin, which has created a robotic island equipped with SMC components, including an innovative wireless control transmission system, is a solid and stimulating technological partnership oriented towards the search for cutting-edge solutions.

By Simona Recanatini

In Grugliasco, in the province of Turin, exactly in the same places where the automotive district that made the Piedmontese city famous throughout the world took shape a few decades ago, is based a company strongly projected on innovation. A challenging company that loves to try new ways and find new technological solutions to stand out and emerge in a highly competitive and complicated world like that of industrial automation today. DMC Automation, a small-to-medium-sized company that nevertheless boasts solid roots and a natural openness towards innovation, has recently moved to a new and modern location, which also marks the beginning of a new course. Let's take a step back: the history of the company began in 1972 with DNC, founded by Domenico De Caroli. In 1992 it began producing machines for the assembly of the metal structure that is in fact the 'skeleton' of car seats: it was a turning point as it marked the entry into a fundamental sector that is still one of the company's core businesses today. All the biggest car seat manufacturers, in fact, use machines supplied by the Turin-based company to make the internal structure of the seat. "We are specialized in the realization of machines for the assembly of this 'skeleton' starting from elements that are composed together and assembled to realize the supporting structure of the seat, an important piece because it allows to satisfy the main safety criteria" explains Carlo Amicilia, sales director of DMC Automation. In 2018, the owner of DNC decides to retire and is succeeded by two young entrepreneurs, Mauro Esposito and Daniele Signoretta, who take over the company and relaunch it, based on a more structured and modern organization. With the change of ownership also comes the transfer to the new headquarters in Grugliasco, a moment that for DMC takes on the symbolic role of the beginning of a new era. As a result of the new, more organised approach, ISO certification also arrives: being able to rely on procedures that follow precise standards is an important business card for DMC to show its customers.

Simplify production

Accelerating and simplifying the production process of different sectors using intelligent technologies is the philosophy with which DMC Automation approaches the market. "We want to work in the field of robotics and automation and we have an in-house design and manufacturing office for the machines and lines we produce.

Everything we design is always pre-assembled and tested in-house and then delivered to the end customer," explains Amicilia. "Our production program is quite articulated: machines and assembly lines for the realization of metal structures of car seats but also robotized assembly and welding lines. Then there are machines and lines for assembly (with processes and technologies that allow to put the pieces together and make a finished product, which are coordinated thanks to SMC components), vision systems, material handling, testing equipment and above all machines and lines made to measure for the individual needs of our customers" explains the manager.

An important partnership

In order to meet the needs of its customers in a precise and timely manner, DMC relies on the support of leading partners. In this path of change that has just begun, the historical collaboration with SMC, world leader in the pneumatic automation sector, is even more important. Thanks to its expertise and constant technological innovation, the Turin-based company is able to respond to customers' requests but also to expand its field of action and approach new market niches. "SMC is a must for us, a fundamental partner and we consider their components a real standard, which facilitates us in the design and allows us to have a continuity of service, spare parts, product updates and much more" underlines Amicilia. "On the one hand, there is the certainty of the quality of their components, but we are also very satisfied with the close collaboration with their team of technicians and salespeople, with whom a real technological partnership has developed over time in both pre and post sales, which has led us to the use of new and cutting-edge products in terms of technological innovation. And this is also an important plus for our customers..." he adds.

An innovative robotic island

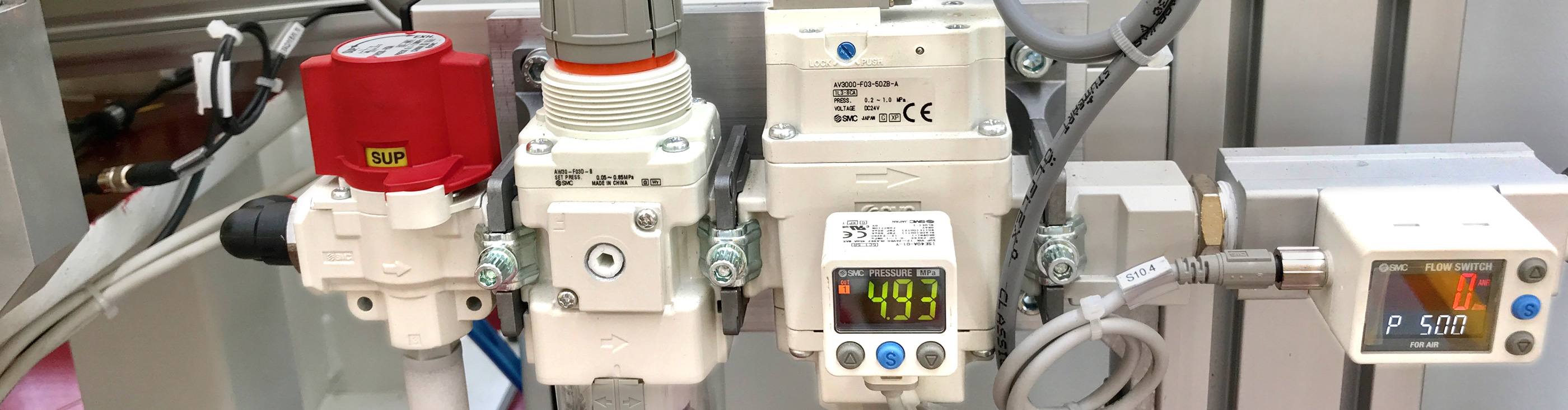

Among the machines produced in the DMC plant in Grugliasco stands out a robotized island equipped with SMC components, characterized by a control transmission system realized through wi-fi, a decidedly avant-garde innovation for the sector. Intended for a Turkish customer, it is a jewel in terms of innovation. "It is an automatic machine for the assembly and testing of a car's rear backrest locking system. It features manual loading stations with presence controls via cameras while all the assembly stations are automatic. There is also a robot for the 'transfer' from a first table to the testing table. Parts are marked and values stored on a PC for traceability. On this machine we decided to use the wireless solenoid valve system that allows us to have the I/Os on board the table without the use of the classic air-electric joint, which is subject to wear and tear, is not easy to maintain and requires a dedicated electrical cabinet that involves additional costs," explains Carmelo Todaro, Technical Office Manager. The heart of the machine consists of a series of electrical connections that are in contact via wi-fi with the central detector, which is able to manage them without contact. From phase to phase the table rotates and consequently all the groups rotate while the central pin remains fixed: every single element is therefore managed in wi-fi through SMC's innovative EX600W.

Effective solutions

"Many of our machines, including this robotic island, are made with rotary tables with different positions that transfer groups, subgroups or components from one workstation to another. One of the problems is the need to maintain control during movement: when moving, the table should carry electrical wires and controls. The jump on wi-fi that SMC proposed to us was really enlightening and epoch-making and allowed us to solve this problem effectively," Carmelo Todaro points out. The technological collaboration with SMC is full of new and innovative solutions. "The SMC flow switch, which monitors air consumption during machine operation, is useful for troubleshooting and monitoring the air consumption in the plant and thus evaluating energy savings. In another application, we used the SMC CKZT series air closures, which allowed us to clamp the entire diameter of the tube so that we could work evenly. Another important product that we use here in DMC are the SMC electric axes, especially the Ley series, which allows us flexibility in positioning and setting up the machine both to us during the pointing phase and to the customer in the various phases of process and part modification" concludes Todaro.

Integration 4.0

A final note: all DMC machines are already designed to meet the requirements of Industry 4.0, an important plus for companies that are already oriented to a production management with sophisticated systems. "For us it is fundamental to rethink and develop new production, organizational and management processes.

This is why our machines are designed to be integrated into our customers' centralized management systems. On this, a bitter reflection: p er absurd we are finding more application, from the point of view of the 4.0 philosophy, in the foreign market: our machines have all the interface modules but it is the international customers who use for example the ethernet cable to connect and manage the machines remotely, the Italians decidedly less. We currently have three lines in Morocco, Romania and Turkey, all three of which have software and IT dialogue modules to demonstrate how much these markets have grown from a technological point of view..." stresses the DMC sales manager.

Published in Technè (Open Factory) October 2019, Italia, written by Simona Recanatini