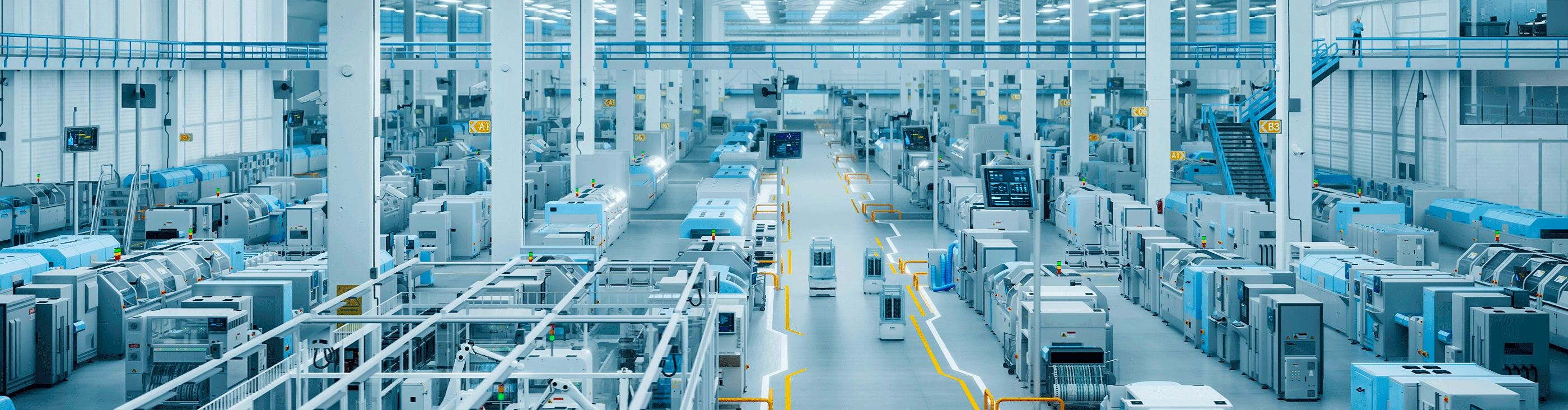

Reducing Energy Costs is Key to Sustainable Manufacturing

High energy costs in industrial manufacturing don’t have to be a given. By optimising existing systems—without investing in new equipment—you can achieve significant energy savings. In a case study, we successfully reduced energy consumption by 28%, simply by fine-tuning the pressure in our compressed air systems. This approach shows that energy efficiency can be improved without costly upgrades to machinery.

By Petr Čečák, Customised Services, SMC Czech Republic

By Petr Čečák, Customised Services, SMC Czech Republic

JULY 2025

Why Is High Air Pressure a Problem?

In many industrial environments, the working pressure of pneumatic systems has been historically set higher than necessary. While 7.5 bar is a common standard, this often leads to excessive energy consumption at the compressor. According to SMC data, reducing the pressure by just 1 bar can lead to energy savings of up to 8%. Maintaining high air pressure means higher energy costs for air compression, which has a significant impact on operational efficiency.

Our solution was simple: optimise the pressure throughout the site to a more efficient level.

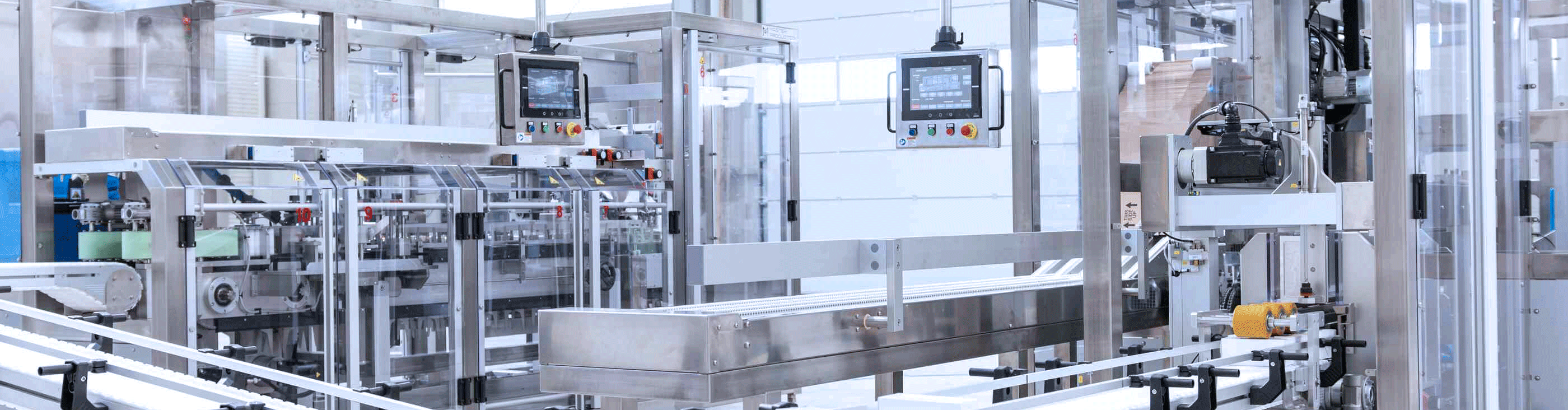

Step-by-Step Pressure optimisation: A Controlled, Risk-Free Approach

We adopted a methodical and safe approach to pressure optimisation. Over six months, supply pressure was gradually reduced by 0.1 bar in stages. This controlled process allowed us to monitor the system’s stability and ensure there were no negative impacts on production. Additionally, we optimise specific areas of the air system by using strategically placed pressure boosters, allowing localise pressure increase for applications requiring higher air pressure (such as vacuum systems, blowers, and some actuators). This ensured overall system pressure could be reduced without compromising performance at critical points.

Results: Energy Savings and Efficiency Improvements

After the optimisation was complete, the results were clear:

- Working Pressure: The original working pressure was 7.5 bar. After the reduction, the pressure was optimise to 6.0 bar, a 1.5 bar decrease.

- Energy Consumption: Before optimisation, the energy required to produce 1 m³ of compressed air was 0.121 kWh. After optimisation, this dropped to 0.087 kWh, representing a 28% reduction in energy consumption.

- No Need for Equipment Modification: Unlike other approaches that often require changes to machinery or new equipment, our solution involved no alterations to the existing machines. The optimisation focused on adjusting pressure levels and enhancing air system efficiency.

- Impact on Productivity: Throughout the entire optimisation process, we saw no reduction in machine performance or productivity.

These energy savings not only helped reduce operating costs but also extended the lifespan of system components, reduced leakage losses, and enhanced overall operational stability. Pressure reduction can also offer improvements in terms of operator safety.

Why Does This Work? Energy optimisation is Both Effective and Environmentally Friendly

Compressed air is one of the most energy-intensive utilities used in manufacturing. In Europe alone, approximately 87 TWh of electricity is consumed annually to produce compressed air, contributing to 84,000 kilotons of CO₂ emissions. Despite this, many systems continue to operate at unnecessarily high pressure levels, leading to excessive energy consumption. By optimising air pressure, we can significantly reduce energy use and carbon emissions, providing both financial and environmental benefits.

Advantages of Reducing Air Pressure in Pneumatic Systems

- Energy Savings: Reducing pressure by just 1 bar can save up to 8% in energy.

- Lower Operating Costs: Immediate reduction in energy consumption directly impacts operational expenses.

- Longer Equipment Lifespan: Proper pressure optimisation reduces wear on components, helping to extend their service life.

- Lower CO₂ Emissions: Decreased energy consumption translates into reduced greenhouse gas emissions.

- Improved Stability and Safety: Reduced pressure means fewer issues with leaks and a more stable operation.

How to Start: A Proven Approach to Pressure optimisation

To begin optimising your system, we recommend the following step-by-step approach:

- Map Current Consumption: Assess current pressure, flow rates, and intake profiles.

- Gradually Reduce Pressure: Lower the pressure in small increments (e.g., 0.1 bar) to ensure system stability.

- Use Supporting Technologies: Impleme nt pressure boosters and air tanks to meet localise high-pressure demands.

- Monitor and Adjust: Continuously monitor system performance and quality to ensure the desired outcomes.

- Set New Standards: Establish new operating pressure standards and select components that support lower pressures.

Optimising individual machines after understanding demands

Optimising individual machines after understanding demands

SMC offers comprehensive support throughout the optimisation process—from initial measurement and system design to implementation and ongoing training.

Common Concerns and How to Address Them

“Our machines are used to higher pressure.” Most modern machines operate efficiently even at lower pressures, such as 4 bar.

“We need higher pressure for certain applications.” Pressure boosters allow for localise increases in pressure where necessary, without affecting the entire system.

“This will be costly and complex.” Reducing pressure is often far more cost-effective than investing in new machinery and can be done without modifying existing equipment.

SMC VBA series pressure boosters

SMC VBA series pressure boosters

Unlock the Potential of Lower Pressure for Maximum Savings

The results from reducing pressure from 7.5 bar to 6.0 bar were clear: a 28% energy saving without compromising productivity. This simple yet effective optimisation can have a major impact on your operational efficiency. If you want to find out how you can reduce costs and improve your energy efficiency, contact us today. Our experts can help you optimise your compressed air system and realise real savings.

SMC – Ready for 4 bar. Ready for a sustainable future. Accept the challenge.