Wireless technology is seeing rapid uptake within the industrial sector, particularly on shop floors where a degree of mobility and freedom is required, such as in robot, automated guided vehicle (AGV) and RFID tracking device applications. But there remain plenty more areas where this technology could make a real difference to operations in terms of reduced costs and increased reliability.

By Alejandro Molinero, Product Manager, SMC Spain

By Alejandro Molinero, Product Manager, SMC Spain

SEPTEMBER 2022

Robust and adaptable

One important thing to point out is that industrial wireless is not the same as the Wi-Fi you have at home. The technology is far more robust and adapted to industrial use, making it more reliable than a wired network in most applications. Here at SMC we’ve worked extremely hard to develop a proven solution with our wireless fieldbus system, which offers up to 1280 I/O for communication with up to 127 remote modules.

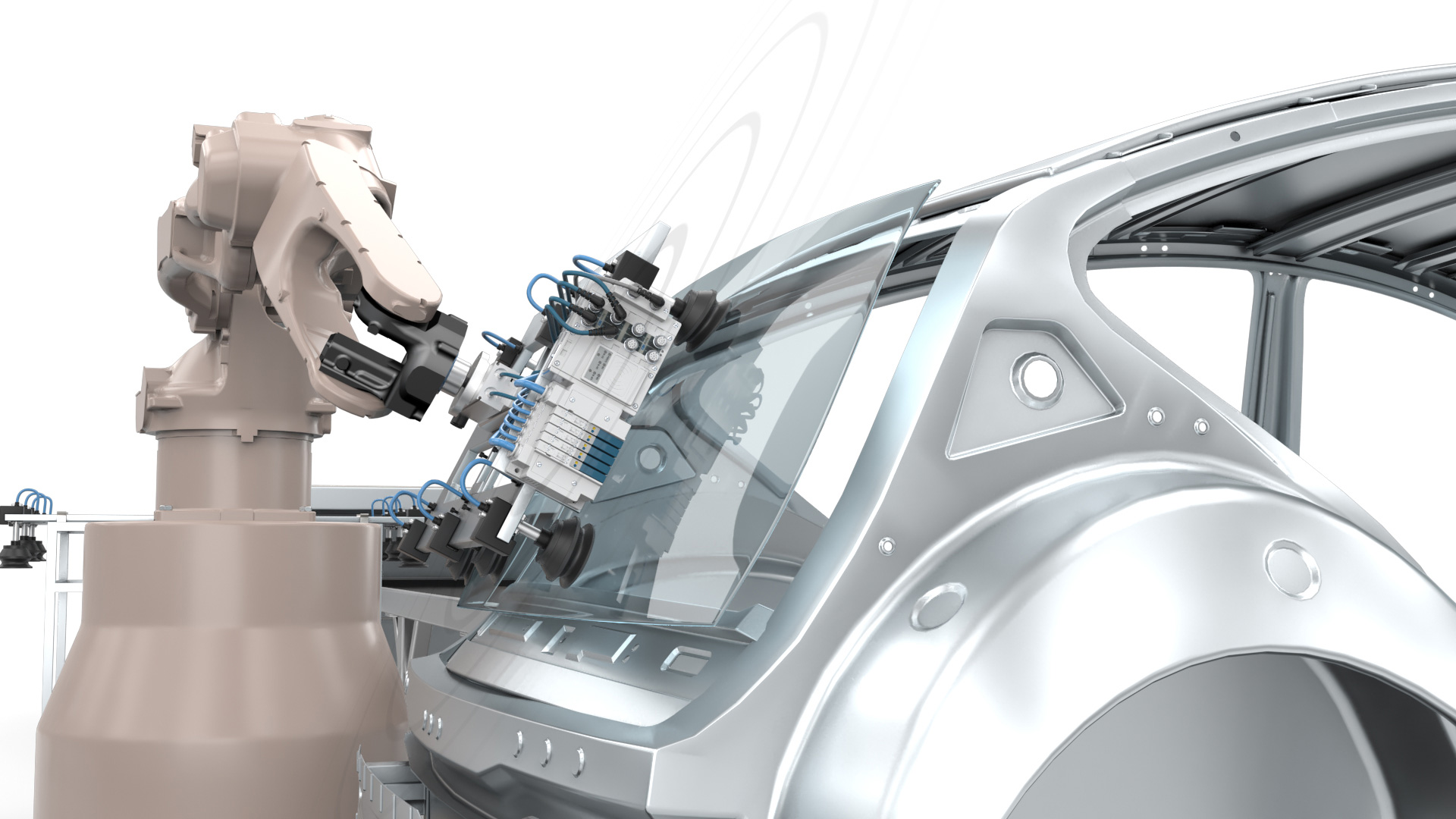

Recreation – SMC´s Wireless Unit in an Automotive plant

Recreation – SMC´s Wireless Unit in an Automotive plant

The system derived from our concept of customer-driven innovation. Customers (originally automotive plants) were asking for a more reliable communication system in the face of wiring fatigue. They knew that the development of such a system would help reduce production downtime and have a positive effect on productivity and OEE. As a result, we set in motion our solution-based approach, driving through the stages of development, testing and validation. Only upon the completion of 100% testing in very demanding environments did we launch the system to the wider marketplace.

Today, a whole host of industrial companies can use the system to take advantage of quicker cabling and connector installation, as well as less breakage and disconnection risk. The result: more reliability! You can also reduce your costs dramatically, concerning both wiring materials and installation work hours. For example, in a use case involving the replacement of a wired system featuring 15 serial interface (SI) units with a wireless system featuring one base unit and 15 remote units, communications lines are reduced from 15 to one, while the number of communication connectors required is reduced from 29 to one. What’s more, with SMC you can maintain interchangeability between SI units.

Transmission frequency selection

There are plenty more benefits available from wireless technology, not least totally noise-resistant communication with frequency hopping (every 5 ms) and data encryption in the 2.4 GHz ISM band.

A vital characteristic of any wireless technology is the transmission frequency as it impacts upon data rate, transmission distance and the ability to pass through objects. Optimal selection of the operating spectrum is therefore crucial to meet the needs of your application. At the 2.5 GHz ISM (industrial, scientific and medical) band, the communication technology rapidly changes (hops) frequency, to prevent interference from any other shop-floor equipment that uses Wi-Fi, even within very noisy industrial environments. As extra peace-of-mind, the system facilitates the monitoring of wireless communications status at all times.

You’ll also enjoy total security as unauthorised access from outside is prevented using data encryption. Here, the data stream is difficult to decode without prior knowledge of the sequence, adding further to security.

You can of course put wireless to work anywhere as there are no cabling limitations. Wireless communication is ideal for tool changes in robot arms, rotary/indexing tables and even welding environments. There really is no reason why you shouldn’t introduce more flexibility into your machines and leverage quick connection capabilities. Indeed, the time from powering up to start of communications is around 250 ms. As an added benefit, configuration file settings are possible using an NFC (near-field communication) reader/writer and setting software. Some parameters can be set even when there is no power supplied.

SMC´s Wireless Remote & Base Unit connected to a 5 Port Solenoid Valve Manifold

SMC´s Wireless Remote & Base Unit connected to a 5 Port Solenoid Valve Manifold

Proven solution

In every application, SMC sets, tests and makes a comparison with wired communications before we propose the best solution. After all, there are lots of factors to consider that require experience and expertise, not least range, speed/performance, reliability, cybersecurity, cost to implement, cost to support and maintain, compatibility with existing systems, and lifecycle.

If we don’t see a benefit, we’ll keep it wired. However, this outcome is becoming more and more infrequent because of the advantages that wireless brings. Not only is downtime lower with wireless communication, it also offers better behaviour in front of any micro-stops, which are becoming an increasingly big concern for industrial companies.

Put simply, in more than 60% of industrial facilities, wireless is more relevant in terms of investment, reliability and flexibility for many of their communication needs. Following professional installation that takes environmental factors into consideration, industrial wireless communication is stable and provides long service life. It even offers a path for the replacement of equipment at either end without changing wireless infrastructure.

SMC has implemented wireless communications at hundreds of industrial facilities in Spain alone. So far we’ve not had a single complaint, which speaks volumes about the reliability of this exciting and advantageous technology.

The adoption of wireless communication is growing at pace. Use cases include cable replacement projects, wireless machine access, connectivity to mobile industrial equipment, and decentralised and flexible architectures. This technology and its association with current and growing industry challenges involving digitalisation, smart factories, flexibility, mobility and data capture, has the potential to unlock new possibilities, optimising factories and improving efficiency in line with enhanced reliability.