Inpeco's revolutionary process automation system for anatomic pathology laboratories reduces the risk of error and increases the productivity of pathologists through end-to-end specimen tracking and automated paraffin block preparation using SMC's precise electric actuators and innovative Thermo-chiller.

As long as reducing errors in healthcare is possible, Inpeco will have a mission to fulfil. This is the commitment of the company that since the 1990s has revolutionized the way clinical laboratories around the world work by focusing on specimen traceability and end-to-end process automation.

Today Inpeco employs 660 people, distributed between its headquarters in Switzerland and dedicated R&D and production sites located in Sardinia and the province of Turin, as well as direct subsidiaries in Germany, Spain, France, Belgium and the United States.

Error-proof traceability and automatic handling

Inpeco's systems have made it possible to reduce human error in hospital and clinical testing laboratories due to mishandling of specimens or data swapping between test tubes, patients and test results.

Alessandra Zucca, Anatomical Pathology Development and Product Manager, explains, "In all of Inpeco's process automation systems, the patient is at the centre of our activity: from his or her identification prior to specimen collection, to the tracking of every operation related to specimen handling and analysis, to specimen archiving. The patient-specimen-test-result traceability chain must never be broken or jeopardized by manual activities to ensure the integrity of clinical information derived from the tests".

Since its first implementations of automated test tube handling systems for clinical laboratories, Inpeco has relied on SMC as its supplier of choice to procure numerous automation components such as grippers, valves, actuators and accessories, which not only meet the required performance requirements, but have ensured over time the level of reliability needed to cope with critical applications such as those in the medical sector.

"The punctuality of the agreed deliveries, even in difficult market conditions, combined with the flexibility offered by the availability of a dedicated warehouse, has allowed us to build and strengthen over time a valued relationship of mutual trust and fruitful collaboration with SMC", testifies Roberto Ferraro, Purchasing Manager at Inpeco.

From clinical laboratories to anatomic pathology laboratories

The approach based on the total integration of patient-oriented processes that has revolutionized the operations of clinical laboratories is now being adopted by Inpeco to enter a new market segment, that of anatomic pathology laboratories, where typically a number of activities are still performed manually, and are therefore unfortunately prone to error.

Anatomic pathology laboratories play an extremely critical role in directing therapeutic choices related to oncologic diseases and must be able to reliably analyse unique and unrepeatable tissue specimens taken from patients. In addition, the demand for histological examinations worldwide is steadily growing, while the availability of trained medical and technical personnel needed to perform this delicate type of examination is not. To help close the productivity gap in anatomic pathology laboratories, Inpeco is developing the world's first solution for complete traceability and automation of all histological specimen preparation and handling activities, with the goal of eliminating human error and increasing the volume of specimens that anatomic pathology laboratories can manage.

The FlexPathTM product suite developed by Inpeco is based on 4 technological pillars: data collection through traceability of each activity, integration of laboratory instrumentation, automation of non-technical activities, and management of specimens and their logistics. For each of these pillars, Inpeco is developing innovative and futuristic solutions to ensure error-free end-to-end automated specimen processing, from specimen collection to reporting and storage.

Automated management of histological specimens

A cornerstone of Inpeco's solution for anatomic pathology laboratories is FlexPathTM Blox, the module that automates all stages of the paraffin wax inclusion operation for histological specimens, allowing the operator to focus exclusively on the delicate task of tissue orientation.

"We wanted to build a machine without compressed air because hospital laboratories require extremely compact and quiet equipment," recalls Alessandra Zucca, "so we looked for the best that electric actuation technology could offer, both in terms of accuracy and repeatability and in terms of reliability. SMC was very helpful in proposing solutions to be implemented on FlexPathTM Blox during the development phase, identifying both high-precision electric actuators and compact electric grippers from the LEHZ family, that were best suited for handling the cassettes and blocks inside the machine, but also for experimenting with innovative solutions for the correct dosing of paraffin wax through the use of two-way solenoid valves from the VX2 family, equipped with special heating elements inside to prevent premature solidification of the paraffin. The paraffin solidification process, in which the specimen is included in the so-called 'block,' is particularly critical, because the reliability of subsequent treatment processes, such as microtomy for cutting the specimen and preparing the slides needed for analysis, depends on its quality. In order to guarantee the highest quality of the block, while at the same time avoiding the manual cleaning of the paraffin residue that is normally required, we have developed a patented cooling system that takes advantage of a Peltier cell HECR Thermo-chiller by SMC to ensure the proper solidification of the paraffin within the required time frame, avoiding the presence of cooling elements at sub-zero temperatures, so there is never any risk of ice formation".

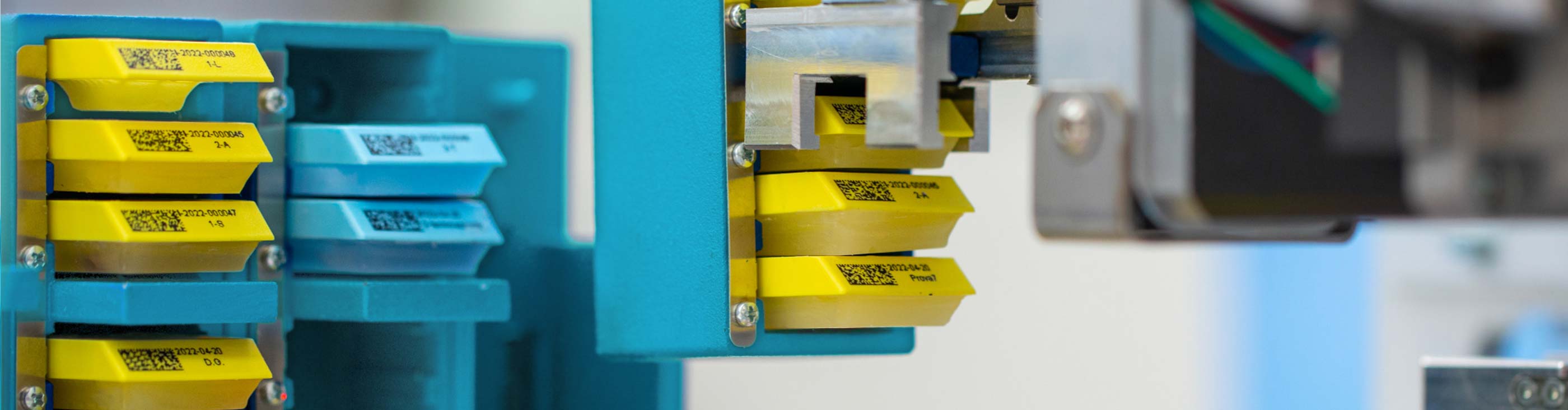

Detail of the LEHZ family of electric grippers by SMC used for the handling of blocks in Inpeco's FlexPathTM Blox machine.

Detail of the LEHZ family of electric grippers by SMC used for the handling of blocks in Inpeco's FlexPathTM Blox machine.

Productivity at the highest level thanks to customized components

The final result of the project is FlexPathTM Blox, a solution capable of automating the non-technical steps of the paraffin block manufacturing cycle, from the reception of the cassettes containing the specimens to be inserted, to the departure of the specimens through a transport management module, containing the blocks with the oriented and inserted specimens, based on pneumatic mail technology for total traceability. FlexPathTM Blox has a throughput of 120 specimens/hour, approximately twice the throughput of a traditional anatomic pathology laboratory, and ensures that only one specimen is handled at a time, eliminating the risk of specimen swapping and contamination between organic material from different patients.

"SMC supported us by developing ad hoc solutions for this project, such as precision electric micro-actuators, demonstrating the exceptional collaborative relationship established between the people working for two companies that are very different in size but share common values: passion for technological innovation and extreme attention to the needs of end customers, which in the case of Inpeco are actually cancer patients, who deserve the highest level of care that science can guarantee them today."

Roberto Ferraro adds, "SMC's global presence and high level of service is another added value for us that has helped and continues to help us provide highly reliable solutions that are installed and supported on all continents".

Daniele Cannamela, Life Science Project Manager at SMC, concludes: "Analysts predict that the anatomic pathology market will grow at a CAGR of 6.4 percent from 2022 to 2028, driven by several factors, including the increasing incidence of cancer and other chronic diseases, the emerging development of personalized medicines that require accurate diagnosis of diseases, and, more generally, the aging population. These market drivers are driving an increasing need for digitization and automation of laboratory processes in general, and anatomic pathology in particular. Inpeco's 30 years of experience in clinical laboratory automation, combined with SMC's application expertise in the world of tissue processing, made it possible to realize a project such as FlexPathTM, which is both innovative and challenging.

SMC electric actuators provide the high level of precision and reliability that is essential for the automated and traceable handling of histology specimens.