By Saeyeong Jeong, European Battery Industry Manager, SMC Europe & Sean Mackenzie, Engineer, SMC European Technical Centre

JUNE 2025

As we observe acceleration in the global transition to eco-friendly energy, the battery industry is emerging as a cornerstone of the future economy. Rapid expansion of electric vehicle adoption, increased use of renewable energy and ongoing technological innovation means the demand for high-performance batteries is soaring.

In response, battery manufacturing technologies are evolving quickly, requiring more precise and efficient production processes. The article ‘Challenges and Opportunities for High-Quality Battery Production at Scale’ published in Nature Communications highlights that maintaining performance, safety and durability is a key challenge in your large-scale battery production processes.

To address these challenges, automation systems optimised for battery cell manufacturing are becoming more crucial than ever before.

The importance of selecting the right automation components

In lithium-ion battery production, scrap rates can vary significantly—approximately 5% for top-tier manufacturers, around 10% for standard producers and even exceeding 30% during initial production ramp-up phases. While many factors contribute to these high scrap rates, one of the most critical is the selection of inappropriate automation components by machine builders or battery plant production engineers.

When you use unsuitable components, scrap rates can rise across all stages of the process—from electrode manufacturing to cell assembly, formation, and battery module and pack assembly—ultimately decreasing overall productivity.

To address this situation, SMC provides automation solutions optimised for your battery manufacturing processes, helping to reduce scrap rates and maximise production efficiency.

25A-series: The optimal choice for high-quality battery manufacturing

Restrictions of materials

Automation components typically feature materials such as aluminium alloys or die-cast metals, which may contain certain amounts of copper or zinc. These metal particles can potentially enter your battery cells due to wear, friction, mechanical stress or heat-induced deformation during component operation. If such particles infiltrate a battery cell, they can cause short circuits or trigger chemical reactions, compromising both quality and safety. Careful consideration is therefore essential when you select automation components.

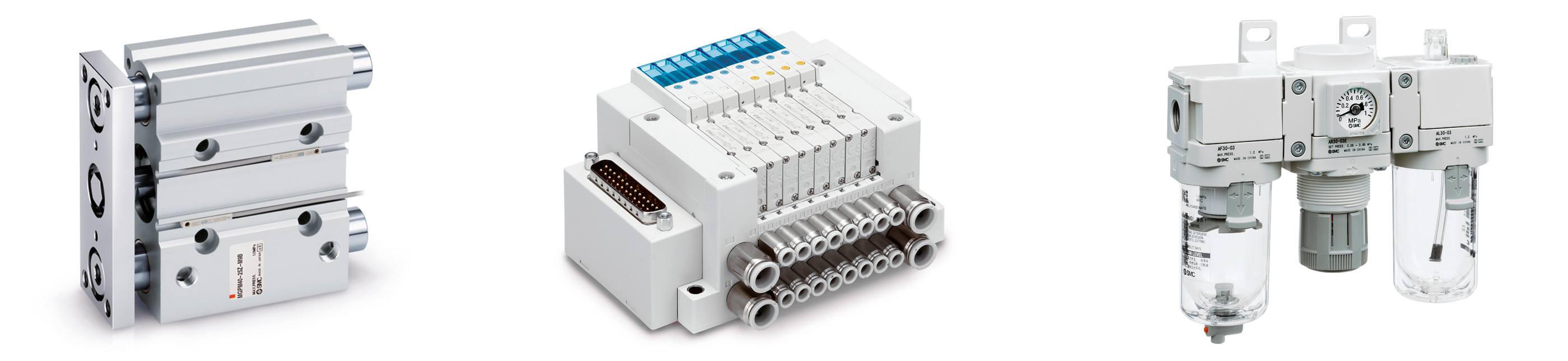

Our 25A-series offers an ideal solution for battery manufacturing environments by restricting the use of metals that primarily contain copper and zinc. The series includes over 200 core models, covering actuators, directional control valves, grippers, fittings and airline equipment—all designed with material restrictions that help minimise contamination risks and ensure safety in your battery production.

SMC´s actuators, compact guide cylinder – 25A-MGP Series

SMC´s actuators, compact guide cylinder – 25A-MGP Series

SMC´s directional control valves, compact 5-port solenoid valve – 25A-JSY Series

SMC´s airline equipment, FRL combination units – 25A-AC-D Series

Dry room: Pay attention to low dew point

In battery cell manufacturing environments, humidity plays a critical role in battery performance and safety. If humidity is too high, the electrolyte can absorb moisture, triggering chemical reactions, corrosion of metal parts and performance degradation. On the other hand, if humidity is too low, the electrodes and separators can dry out, leading to cracks and reduced conductivity, which ultimately lowers battery efficiency.

As a result, battery production typically takes place in specialised environments known as dry rooms. In these environments, the dew point pressure is maintained below -50°C, which is essential for preventing electrolyte contamination and maximising your battery quality. However, in such environments, issues like the evaporation of lubricants in automation components or hardening of sealing materials can arise, causing operational problems with equipment.

To address these challenges, it’s crucial to select automation components that use greases suitable for low dew point environments.

SMC’s 25A-series features greases that can operate effectively even at dew points as low as -80°C. This capability ensures components maintain the same durability and performance in special environments like battery manufacturing as they would in standard production settings. The result? You get to enjoy better stability of your manufacturing process and the effective prevention of productivity and quality degradation issues.

Additional solutions for battery manufacturing

We can offer many innovative solutions to address safety and efficiency challenges that arise in the battery manufacturing process. SMC helps build a safe and stable manufacturing environment through a diverse range of products with characteristics that include: explosion proof; corrosion resistance; electrostatic discharge prevention; temperature control for laser applications; wireless communication systems; and air management systems. These solutions contribute to higher productivity and lower costs.

More specifically, consumption monitoring via systems such as air management plays a crucial role not only in enhancing energy efficiency but also in supporting digitalisation. This capability establishes the foundation for developing predictive maintenance strategies. Furthermore, the SMC open wireless system (OPC-UA) is engineered to collect data from IO-Link technology sensors, even when they do not belong to our product portfolio.

SMC´s Air Management System – 25A-AMS20/30/40/60 Series

SMC´s Air Management System – 25A-AMS20/30/40/60 Series

Explosion proof and corrosion resistant

The electrolyte filling process for battery cells is a high-risk operation for fire or explosion due to the low ignition point of the electrolyte. Additionally, during the formation process, where the battery activates through repeated charging and discharging, there is a risk of thermal runaway and ignition. To address this, we offer ATEX-certified components (such as cylinders, solenoid valves, pressure switches) to ensure safety in these critical operations.

Furthermore, some automation components can suffer corrosion or hardening when exposed to the chemicals used in your battery manufacturing, such as electrolytes, over long periods. This can make components vulnerable to external impact and vibration, potentially generating contaminants. Products with excellent corrosion and chemical resistance are therefore necessary, depending on the process. For example, high-purity products – as well as stainless steel cylinders and fittings – are essential. We offer components that provide outstanding corrosion and chemical resistance for battery manufacturing environments.

SMC´s corrosion resistant solutions, stainless steel cylinder – CG5-S/CJ5-S Series

SMC´s corrosion resistant solutions, stainless steel cylinder – CG5-S/CJ5-S Series

Electrostatic discharge solutions

In extremely dry environments, such as battery manufacturing, static electricity can accumulate easily. The static charge that accumulates on your battery cells can increase the risk of explosions and fires in production or generate incorrect readings during voltage testing, leading to quality issues. To address this situation, we offer a variety of ionizers (including bars, nozzles, fans) that can quickly eliminate and control static electricity. We also offer anti-static equipment(product).

SMC’s bar type ionizer – IZS51 Series

SMC’s bar type ionizer – IZS51 Series

SMC’s slim bar type ionizer, separate controller – IZT44/45 Series

SMC´s nozzle type ionizer – IZN10E Series

Temperature control solutions

In processes such as laser-based notching or tab welding during cell assembly, precise temperature control is essential to prevent issues caused by overheating of the laser oscillator. Additionally, during the activation process (charging and discharging, ageing), maintaining a precise room temperature can enhance the characteristics and quality of your battery cells.

Our thermo chillers help maintain the equipment's temperature within a strict range in these processes, contributing to improved productivity and quality.

SMC´s non F-Gas (CO2 refrigerant) thermo-chiller, standard type – HRSC Series

SMC´s non F-Gas (CO2 refrigerant) thermo-chiller, standard type – HRSC Series

Wireless communication for flexible and reliable battery cell handling

In demanding battery manufacturing environments - characterised by fast movements, rotating elements and tight spaces - cabled communication can be prone to wear, disconnection and maintenance issues. This is especially true for robotic grippers and handling systems for battery cells.

The SMC Wireless Fieldbus System offers a robust solution by replacing conventional wired communication with secure and reliable wireless transmission. Adopting the system eliminates the need for complex cable routing on moving parts, significantly reducing your maintenance costs and enabling more compact and flexible equipment designs.

By adopting wireless communication, you can achieve higher uptime, greater design freedom and better reliability in critical handling systems – all while simplifying installation and system integration.

SMC´s wireless system, compact type – EXW1 Series

SMC´s wireless system, compact type – EXW1 Series

Battery of expertise

With over 20 years of experience collaborating with industry-leading companies in the battery manufacturing sector, SMC provides automation components optimised for battery cell production. Based on a deep understanding of the battery manufacturing process, we contribute to reducing defect rates, improving safety and increasing equipment uptime through bespoke solutions, from initial equipment design to the mass production of your battery cells.

Furthermore, our solutions meet modern requirements, including predictive maintenance strategies and factory digitalisation.